National defense

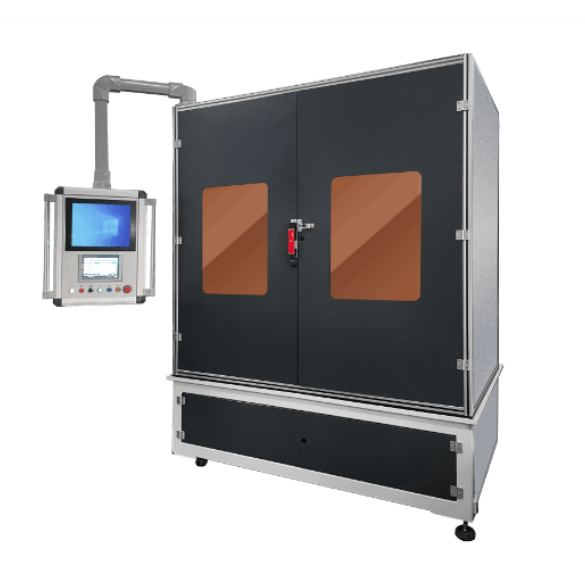

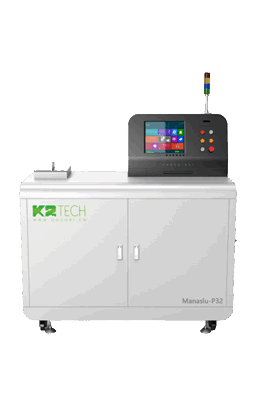

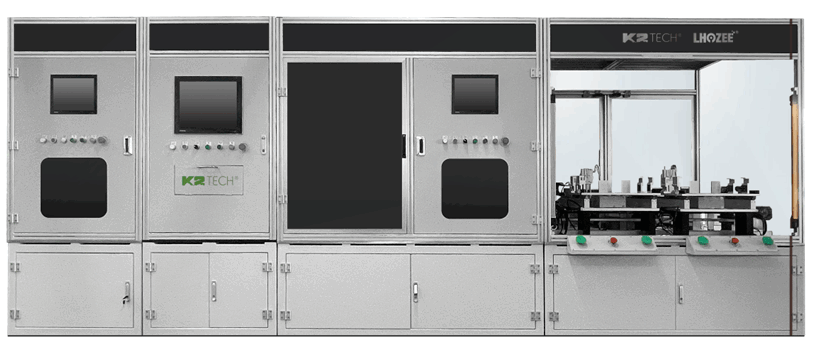

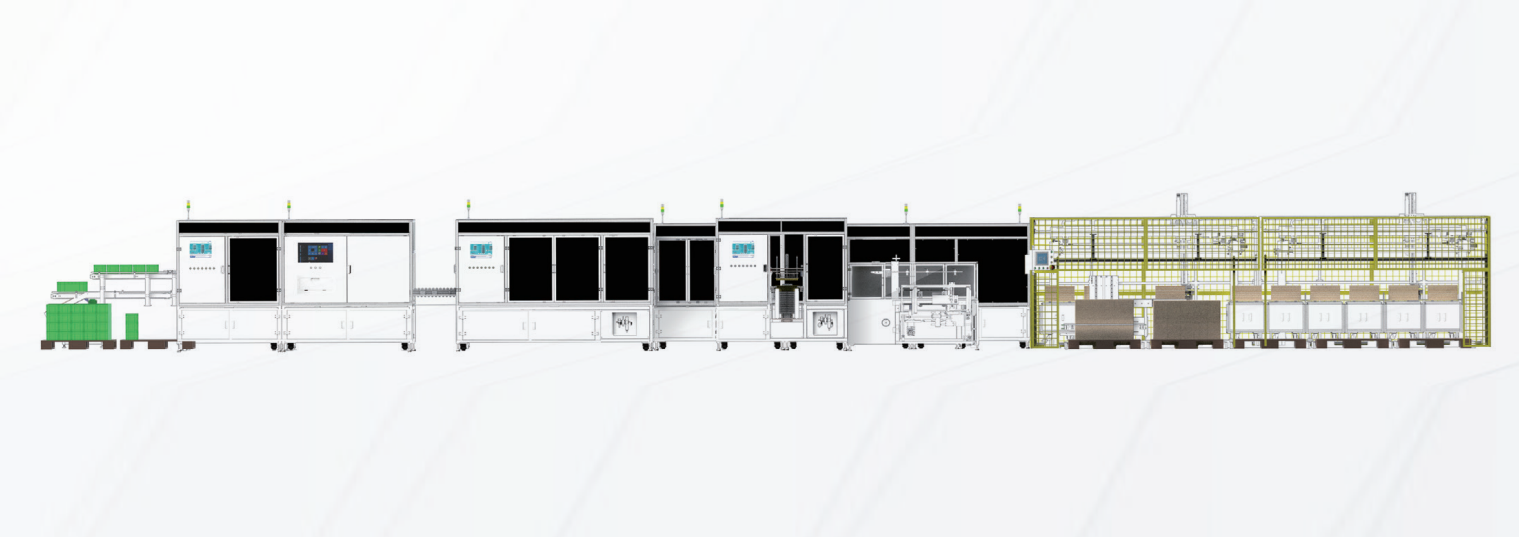

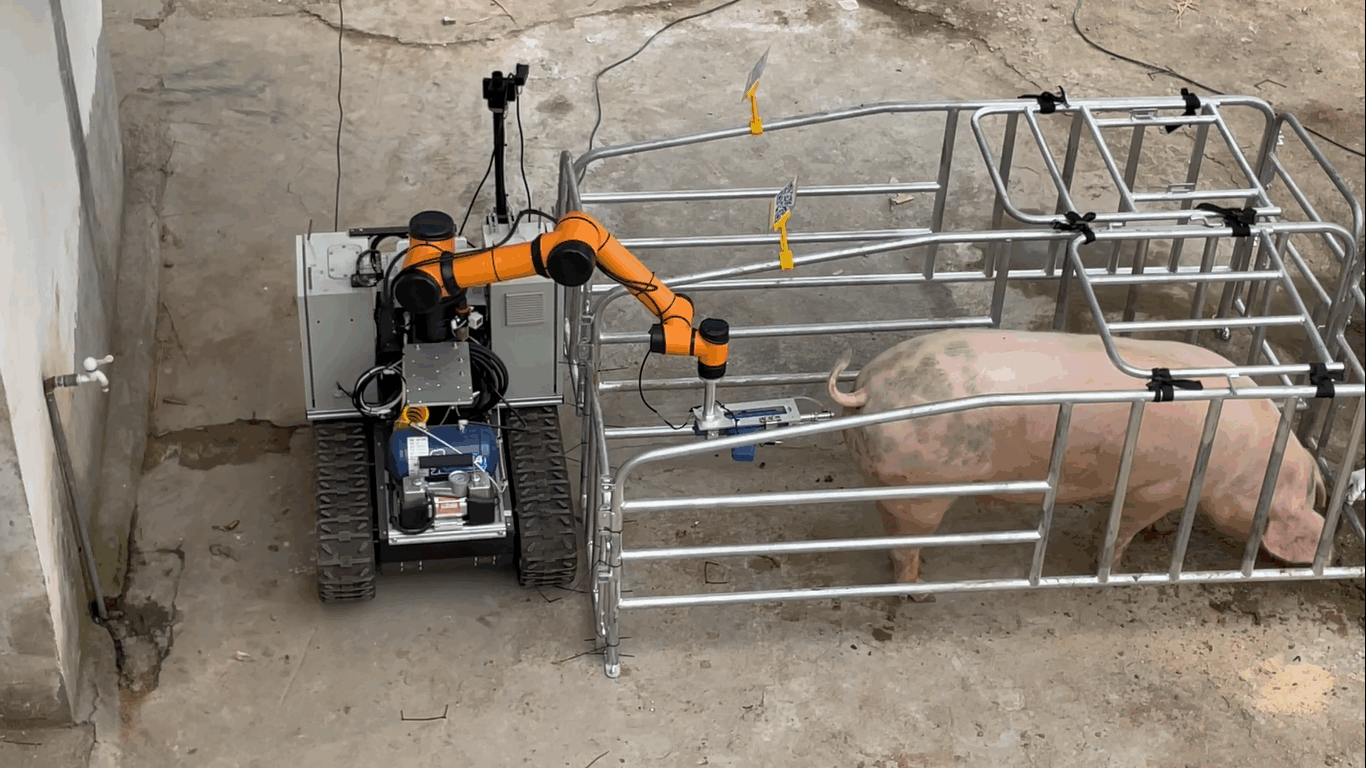

Since its establishment, K2 Tech has successfully developed intelligent inspection equipment in a number of industries, including the aerospace group, aviation group, military enterprises, many large listed companies and foreign enterprises to solve the quality testing problems in the manufacturing process. One equipment can meet the needs of various complex detection applications.The equipment can be customized according to customer needs,with many flexible options including vision, detection, identification and positioning, robot control and so on. Access to advanced function can be realized by simple software upgradation.

Machine Vision

Machine Vision Bearing

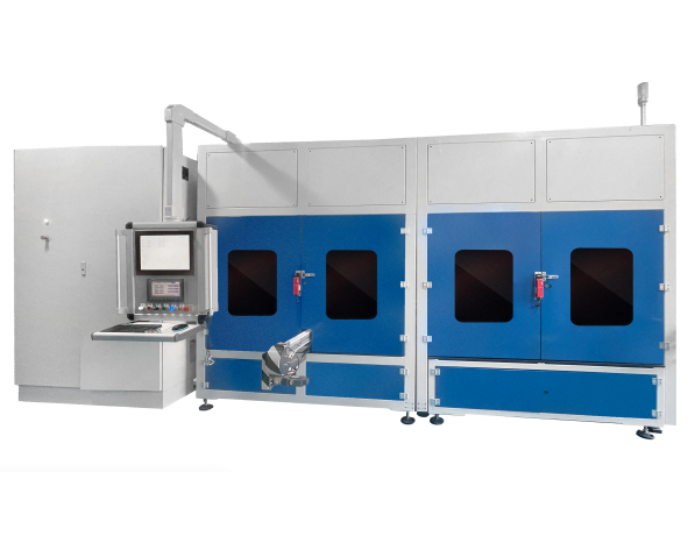

Bearing AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI MACHINE FOR Wheel Hub Bearing Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Sealing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS

AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI MACHINE FOR Wheel Hub Bearing Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Sealing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS